Featured Articles

2023-07-07

[2023-07-07 ~

]

The Development of High-efficiency Hydrogen Tanks to Improve the Endurance of Vehicles

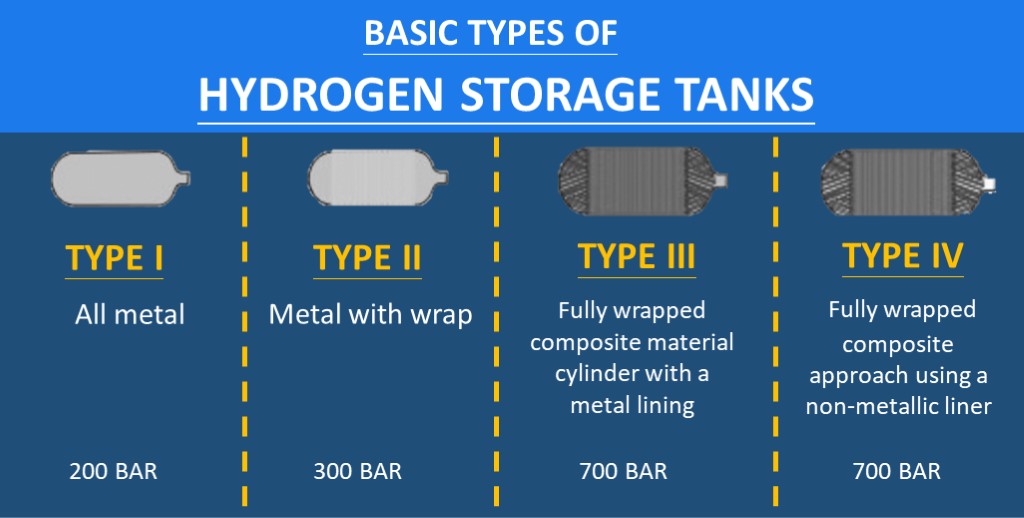

The American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO) classify the pressure vessel's type and structure into five types.

Type I containers adopt an all-metal design. The biggest feature is that they can be built in huge sizes and occupy a large area, but they are the most cost-effective. According to different specifications, it can be suitable for 200 Bar low pressure, even for 1000 Bar high-pressure gas storage.

Type II is also made of metal, and the difference from Type I is that it is wrapped around the straight part with a composite material. Standard tanks typically have a maximum pressure of 300 bar. Like Type, I, the ratio of stored gas quality to cylinder quality is very low.

Type III is a fully wrapped composite material cylinder with a metal lining. The capacity is four times that of the standard

Type I container and cannot bear weight. The maximum pressure of a standard storage tank is usually 700 bar.

Type IV is a fully wrapped composite approach using a non-metallic liner, with the same effective storage capacity as Type III. Usually constructed of a polymer such as high-density polyethylene, they are extremely costly and typically have a maximum pressure rating of 700 bar.

Type V is an unlined, all-composite structure that is still in its infancy.

Type I has more than 90% of the pressure vessel market share, but the situation has been changing in recent years. As the hydrogen fuel market is getting hotter, there is an urgent need to use composite materials to reduce weight and improve compressed gas storage efficiency. Type III and Type IV containers have gradually become the focus of the development of the industry for storing high-pressure containers. The Type V is still in development and is intended primarily for space applications.

At present, hydrogen fuel usually needs to be stored in a gaseous form in a large-capacity system. For stationary applications, the footprint is usually not limited, which is not the problem and is not the focus of industry research. However, fuel cell-powered vehicles need enough hydrogen to provide a driving range of more than 500 kilometers, and can complete hydrogen refueling within 3 to 5 minutes, which is a great challenge for hydrogen storage tanks. On a mass basis, at 120 MJ/kg for hydrogen and 44 MJ/kg for gasoline, hydrogen has almost three times the energy content of gasoline. But in terms of volume, the opposite is true, liquid hydrogen has a density of 8 MJ/L, while gasoline has a density of 32 MJ/L. With a driving distance of about 500 kilometers, a hydrogen vehicle needs more than 5 kilograms of hydrogen, and a storage system with a pressure of 700 bar will have a volume of at least 200 liters, or 3-4 times the volume of a gasoline tank. Conceptually, the high pressure of 700 bar is equivalent to an area of 1 square meter, which can withstand the pressure of 7 strong adults with a weight of 100 kg each.

Reference:

Hydrogen Fuel News, 2022-06-10, Tamy Hood, Toyota subsidiary Woven Planet creates exchangeable hydrogen cartridge

Auto evolution, 2022-05-13, Gustavo Henrique Ruffo, NamX HUV Proposes Swappable Hydrogen Capsules to Make FCEVs Practical

Hydrogen Center, 2021-09-09, Plastic Omnium wins a Major Contract With Hyundai to Supply High-end Hydrogen Vessels

Transmission Time, 2023-03-13, Kihoon Kim, Iljin Hysolus CEO "Hydrogen is not dangerous... Ultra-high pressure tank competitiveness"

日経クロステック/日経Automotive 久米秀尚, 2022-08-10, 3本合計110kgで距離30%延長 トヨタ「ミライ」の水素タンク

日経 XTECH 2015-06-25伊東敏夫トヨタのFCV「ミライ」、高圧水素タンクの炭素繊維4割削減

ASIAE, 2022-04-18, Kwak Min-Jae, Hydrogen tank technology ahead of Toyota..."If we cross the threshold, we will surpass electric vehicles"

Kurdo, 2021-11-08, Iljin Hisolus supplies hydrogen tanks to BMW following Hyundai Motors

Seoul Financial, 2022-09-22, Jin Wook Kwon, Iljin Hysolus participates in 'H2 MEET 2022' ... Hydrogen tank with stability and performance

Entreprises, 2023-05-30, Victor Cazale, Plastic Omnium, futur géant de l’hydrogène ?